COPYRIGHT©广州慧正云科技有限公司 www.hzeyun.com 粤ICP备18136962号 增值电信业务经营许可证:粤B2-20201000

来源: 浙江金纬管道设备制造有限公司 2025-03-18 10:43

慧正资讯:近年来,热塑性聚氨酯(TPU)作为一种兼具橡胶弹性和塑料加工性能的高分子材料,凭借其卓越的物理和化学特性,在多个领域得到了广泛应用。金纬机械作为行业内的领军企业,凭借其先进的TPU膜生产线和创新技术,为TPU膜的生产提供了强大的技术支持。

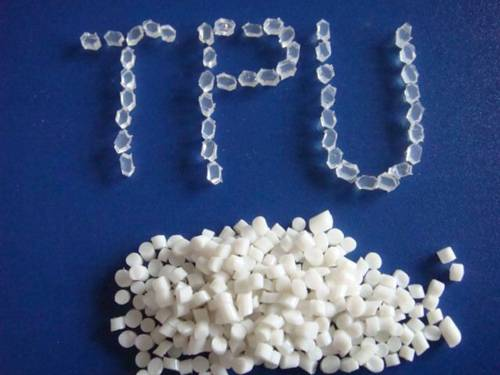

1、TPU原料介绍

TPU(热塑性聚氨酯)是一种兼具橡胶弹性与塑料加工性能的高分子材料,分为聚酯和聚醚两大类型。同时具备以下特性:

• 环保无毒:可回收利用,符合欧盟 RoHS、REACH 等环保标准;

• 卓越弹性:断裂伸长率高达 500%-800%,耐反复拉伸;

• 耐磨抗腐蚀:耐磨性能是天然橡胶的 3-5 倍;

• 宽温域适应性:使用温度范围 - 40℃至 120℃。

Introduction to TPU Raw Materials

TPU (Thermoplastic Polyurethane) is a kind of polymer material that combines the elasticity of rubber and the processing performance of plastics. It is divided into two major types: polyester and polyether. It also has the following characteristics:

• Environmentally friendly and non-toxic: It can be recycled and meets environmental protection standards such as RoHS and REACH in the European Union.

• Excellent elasticity: The elongation at break is as high as 500%-800%, and it is resistant to repeated stretching.

• Abrasion resistance and corrosion resistance: The abrasion resistance is 3-5 times that of natural rubber.

• Wide temperature range adaptability: The operating temperature range is from -40°C to 120°C.

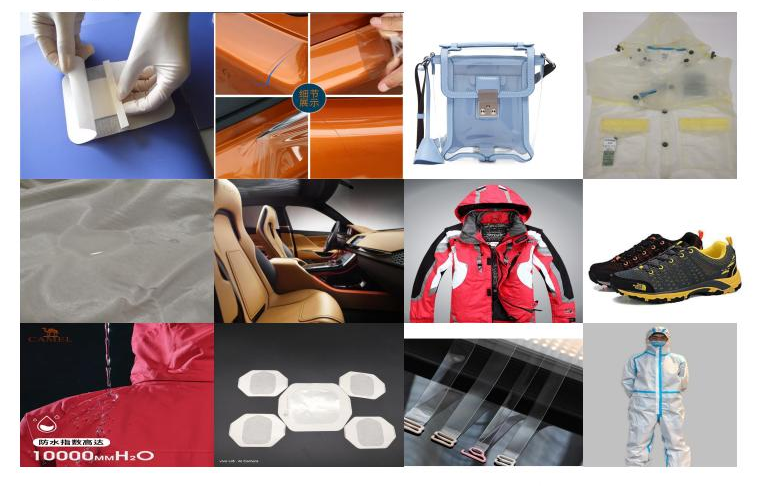

2、TPU 膜的核心优势:不止于 “膜”

弹性与柔韧性:适用于动态环境(如运动装备、医疗器械);

防水透气:微孔结构实现水汽交换,用于户外服装、鞋材;

耐候性强:抗紫外线、耐黄变,延长产品寿命;

粘接性佳:与金属、布料、塑料等基材附着力优异。

Core Advantages of TPU Film: More Than Just a "Film"

Elasticity and flexibility: Suitable for dynamic environments (such as sports equipment, medical devices).

Waterproof and breathable: The microporous structure enables water vapor exchange, and it is used in outdoor clothing and footwear materials.

Strong weather resistance: It is resistant to ultraviolet rays and yellowing, extending the product's lifespan.

Good adhesion: It has excellent adhesion to substrates such as metals, fabrics, and plastics.

3、TPU 膜的应用场景:渗透生活的方方面面

4、TPU 膜市场分析:需求爆发与技术升级

• 全球市场:2023 年规模超150 亿美元,预计 2030 年将突破250 亿美元,年复合增长率 6.8%(数据来源:Grand View Research);

• 区域增长:亚太地区占比超 50%,中国是全球最大生产和消费国;

• 驱动因素:新能源汽车、可穿戴设备、环保政策(如限塑令)推动需求增长。

Market Analysis of TPU Film: Demand Surge and Technological Upgrades

• Global market: The market size exceeded 15 billion US dollars in 2023, and it is expected to exceed 25 billion US dollars in 2030, with a compound annual growth rate of 6.8% (Data source: Grand View Research).

• Regional growth: The Asia-Pacific region accounts for more than 50%, and China is the world's largest producer and consumer.

• Driving factors: New energy vehicles, wearable devices, and environmental protection policies (such as the plastic restriction order) drive the demand growth.

5、TPU 膜生产线:工艺决定品质,技术引领未来

金纬公司 TPU 膜生产线采用智能化、高精度工艺,核心优势如下:

挤出系统:

• 单螺杆挤出机实现物料均匀塑化,温控精度 ±1℃;

• 优质模具钢,厚度偏差≤±2%。

流延 / 压延工艺:

• 气刀 + 真空吸附技术确保薄膜平整度;

• 多辊压延系统,快速冷却维持制品表面张力。

后处理技术:

• 在线测厚 + 张力闭环控制,实时调整参数;

• 电晕处理增强表面附着力,满足复合需求。

节能设计:

• 伺服驱动系统比传统设备节能 10% 以上;

TPU Film Production Line: Process Determines Quality, Technology Leads the Future

The TPU film production line of Jinwei Company adopts intelligent and high-precision processes, with the following core advantages:

Extrusion system:

• The single-screw extruder realizes uniform plasticization of materials, with a temperature control accuracy of ±1°C.

• High-quality mold steel, with a thickness deviation ≤ ±2%.

Casting/calendering process:

• The air knife + vacuum adsorption technology ensures the flatness of the film.

• The multi-roll calendering system rapidly cools to maintain the surface tension of the product.

Post-processing technology:

• Online thickness measurement + tension closed-loop control, adjusting parameters in real time.

• Corona treatment enhances surface adhesion to meet lamination requirements.

Energy-saving design:

• The servo drive system saves more than 10% energy compared with traditional equipment.

• The waste heat recovery technology reduces energy consumption costs