Polyplastics Launches New Glass-Filled PPS Grade with Improved Thermal Shock Resistance

2024-05-23 08:41

Polyplastics, a global leader in engineering plastics, has announced the launch of a next-generation polyphenylene sulfide (PPS) grade that boasts significantly improved thermal shock resistance and can be easily recycled during post-consumer recycling (PCR) without sorting. DURAFIDE? PPS 1140HS6, a 40% glass-filled grade, meets the requirements for metal insert molding, particularly busbars for electric vehicles (xEVs).

DURAFIDE? PPS 1140HS6 can be easily collected without being separated from other PPS components during recycling. Polyplastics has employed a material design technique to ensure thermal shock resistance by minimizing residual strain during molding and homogenizing linear expansion to mitigate internal stress. As a result, thermal shock resistance has been improved while retaining mechanical and other essential properties.

DURAFIDE? PPS 1140HS6 eliminates molding imperfections and enhances performance without the need for impact modifiers in xEV busbar applications. Insert molded xEV components conduct high-voltage currents in various electrical parts and their complex shapes make them susceptible to cracking. They are usually made up of a metal that conducts electric power and PPS resin that functions as a coating for insulation. This cracking problem is caused by repeated heating and cooling and subsequent rapid temperature changes. This is a significant issue, leading to insulation failure, particularly in the critical parts of xEVs that conduct high-voltage currents.

The typical solution is to add impact modifiers to PPS. Still, this approach has drawbacks, such as a reduction in material strength and the tendency for gases and mold deposits to emerge during molding. Additionally, materials containing impact modifiers are incompatible with the growing trend of material recycling.

The newly developed DURAFIDE? 1140HS6 PPS resin offers better flowability during injection molding than standard materials. This makes it an ideal choice for molding both thin-wall and large products.

For more information

Polyplastics has developed a new material called DURAFIDE? PPS 1140HS6 that can aid in the transition towards mono-materials*1. It has significantly improved thermal shock resistance and can be easily recycled during post-consumer recycling (PCR)*2 without sorting. This grade has been engineered to improve thermal shock resistance while maintaining the ISO labeling of PPS global standard >PPS-GF40< and retaining the same mechanical and other basic properties.

*1: Mono-material: Generally refers to a single material that constitutes a product, but we believe that one of the objectives of mono-materialization includes improving sorting and recovery by widely using a single resin or a grade with a general-purpose composition in consideration of recyclability. In the case of PPS, since PPS GF40% is widely used in injection molding applications, this material is defined as a mono-material in this report because it has the same composition as general PPS GF40% without impact modifier.

*2: Post-consumer recycling involves collecting used products from the market and recycling them.

Balances the shift to mono-materials with thermal shock resistance

Polyphenylene sulfide resin, or PPS, is a resin that is highly resistant to heat and very durable, making it useful in a wide range of industries. It is commonly used in automotive parts that require resistance to high temperatures, plumbing components that need to withstand fluctuations in hot and cold water, and connectors that require heat resistance during surface-mount technology (SMT) processes. To improve its properties, PPS can be enhanced with different additive materials or reinforced with inorganic materials like glass fibers. Different grades of PPS are available on the market, each with different additives depending on the application. However, given the growing concerns about environmental problems, there is a trend towards using mono-materials to address recyclability. At Polyplastics, we have developed a new grade of PPS, called DURAFIDE? PPS 1140HS6, designed to meet these challenges.

Eliminates molding imperfections and enhances performance without the need for impact resistance modifiers

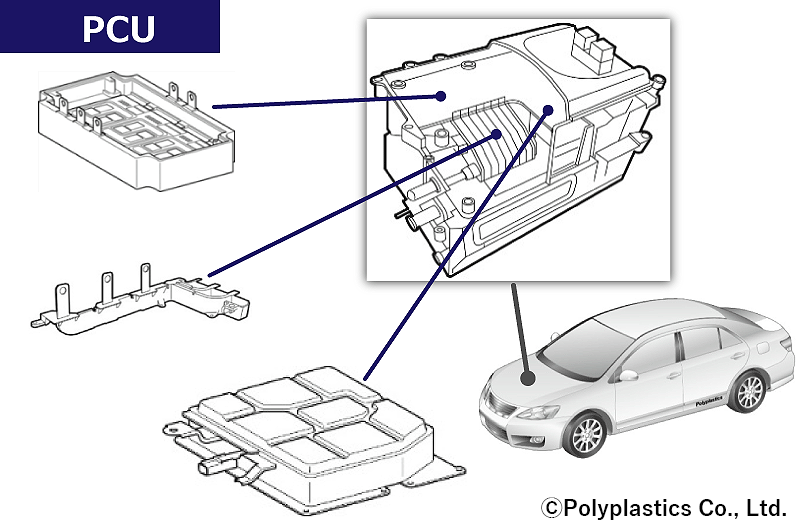

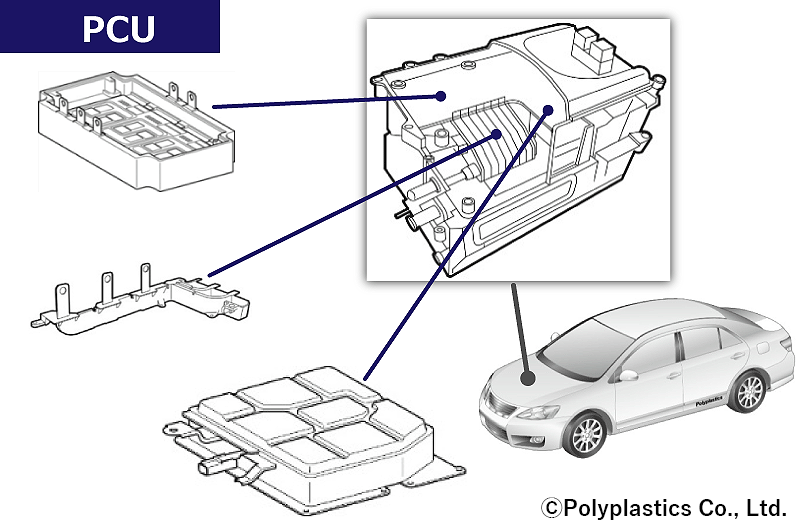

The demand for PPS (polyphenylene sulfide) in automotive applications has increased recently, especially for busbars. This is due to the rise in the production of electric vehicles (xEVs). Busbars conduct high-voltage currents in various electrical parts like xEV motors, power control units, and lithium-ion batteries. They are usually made up of a metal that conducts electric power and resin that functions as a coating for insulation. These components are typically produced using insert molding, which combines the metal and resin via injection molding. However, these parts tend to break down due to the strain caused by the difference in linear expansion rates between the two types of materials. This problem is caused by repeated heating and cooling and subsequent rapid temperature changes. (as shown in Figure 1). Therefore, they need to be resistant to thermal shock.

Figure 1: Illustration of the thermal shock phenomena

PPS is an engineering plastic that has exceptional thermal shock resistance. However, insert xEV components have complex shapes that make them susceptible to cracking. This is a significant issue, leading to insulation failure, particularly in the critical parts of xEVs that conduct high-voltage currents. The typical solution is to add impact resistance modifiers to PPS. Still, this approach has drawbacks, such as a reduction in material strength and the tendency for gases and mold deposits to emerge during molding. Additionally, materials containing impact resistance modifiers are incompatible with the growing trend of material recycling*3.

*3 Material recycling: Reusing used products without changing their characteristics. Examples include melting down metals and discarded plastics to be reworked into new products.

Features of DURAFIDE? PPS 1140HS6

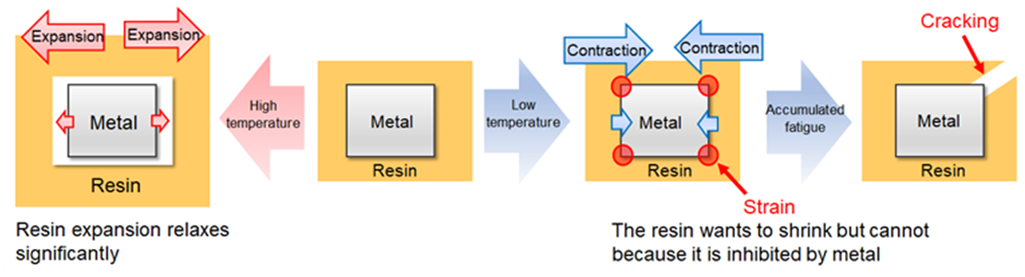

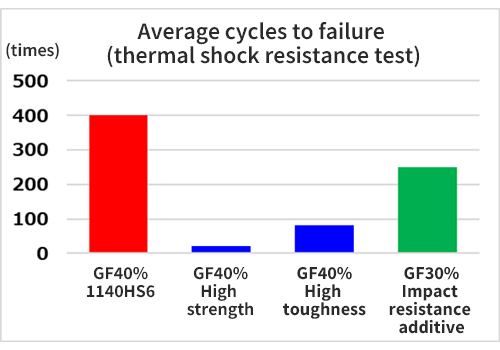

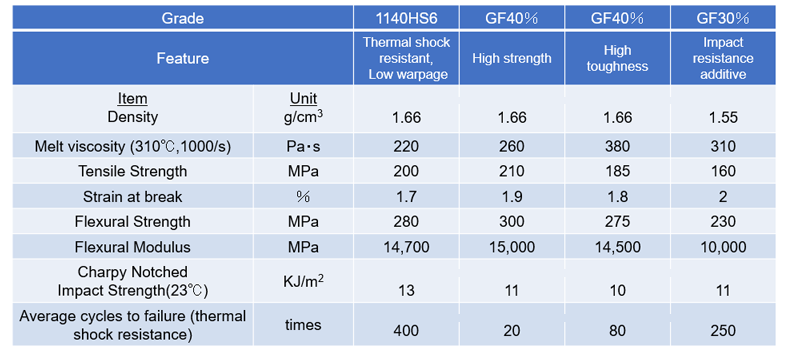

We utilized a PPS standard material containing 40% glass fiber reinforcement (GF) and excellent thermal shock resistance. This material can be easily collected without being separated from other PPS components during PCR. For the first time, we employed a material design technique to ensure thermal shock resistance by minimizing residual strain during molding and homogenizing linear expansion to mitigate internal stress. As a result, we have successfully improved thermal shock resistance while retaining mechanical and other essential properties, as shown in Table 1 and Figure 2.

Figure 2: Thermal shock resistance of DURAFIDE? PPS 1140HS6 and current GF40% grades

Table 1: List of physical properties of DURAFIDE? PPS 1140HS6 and other grades

The newly developed DURAFIDE? 1140HS6 is a promising next-generation PPS resin that offers better flowability during injection molding than standard materials. This makes it an ideal choice for molding both thin-walled and large products. It is also environmentally friendly and suitable for use as insulation material in metal insert parts, including peripheral components in xEVs.

Developing high-performance materials that meet environmental needs is a continuous effort, and we remain committed to this goal.

More Hzinfo

- Recommended products:D-Ray New Materials Cobalt Blue(P.B.28)

- Cobalt Blue is a blue pigment which is calcined at high temperature, it has good performance like excellent chemical resistance, outdoor durability, sunlight resistance, thermal stability, non-bleedin

-

2025-02-24

- Secretary Lu Weidong conducted research and condolences to Dynamic Chemical during the Spring Festival

- On February 1, 2025,our company welcomed a delegation led by Lu Weidong, a member of the Standing Committee of the Municipal Party Committee.

-

2025-02-21

- Looking back and looking ahead, gathering strength again, and striving to compose a new chapter

- On January 11, 2025, the company held a mid level performance evaluation meeting for 2024, where senior management gathered to learn from the achievements of 2024 and draw a blueprint for the future.

-

2025-02-21

English

English 简体中文

简体中文 Русский

Русский إنجليزي

إنجليزي