Recommended products: Tengrui Zhike Abrasion Tester TR 5307

2024-09-29 10:34

The abrasion tester produced by Tenrui Zhike is designed in accordance with GB/T 1768, ISO 7784-2, ISO 9352, ASTM D3884, ASTM D1175 and other standards. In actual use, the coating is often subject to mechanical wear from sand and gravel friction or other media. The wear resistance of the coating refers to the ability of the coating to resist friction, that is, the embodiment of the comprehensive effect of the coating hardness, adhesion and cohesion. It is also related to the type of substrate, surface treatment, temperature and humidity during the drying process of the paint film.

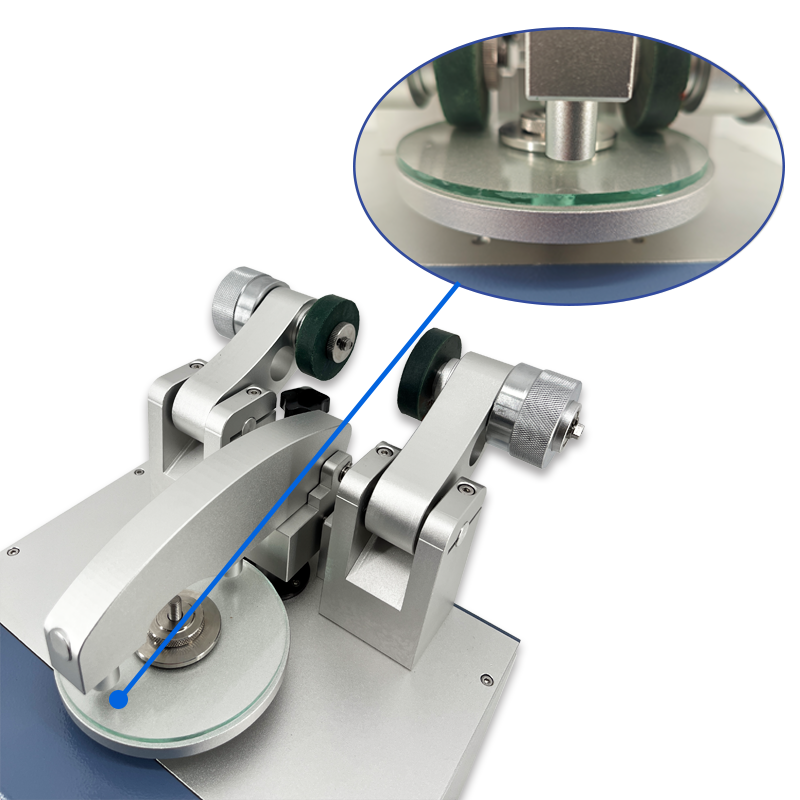

The TR 5307 abrasion tester is carefully designed with reference to similar foreign products and combined with actual domestic use methods. It is easy to operate, has a smooth appearance, and stable performance, and can be comparable to similar foreign products. It is mainly suitable for the determination of the wear resistance of the paint film. Its principle is to measure the mass loss or thickness loss or light transmittance of the material after a specified number of rotations under a certain load to evaluate the wear resistance of its products.

Product features:

·4.3-inch color touch screen display control.

·Buzzer safety reminder before the instrument is started.

·Various abrasive media and accessories can be selected for different tests.

·Two dust suction nozzles are used, and the height is adjustable to suit samples of different thicknesses.

·Strict product quality control before leaving the factory ensures reliable test results.

·The grinding wheel device can be used for grinding wheels from domestic and foreign manufacturers.

Product parameters:

·Working disk speed: 5~100 rpm (speed can be set arbitrarily).

·Counting range: 0~99999 rpm.

·Sample chassis: Φ102.8 mm.

·Test glass sheet: Φ100x3mm (center hole Φ9mm).

·Motor power: 25W.

·Power supply: 220V; 50Hz / 110V; 50hz.

·Instrument dimensions (LxWxH): 255mmx350mmx296mm.

Standard configuration:

·1 set of vacuum cleaner for removing grinding chips.

·A pair of imported Taber CS-10 or CS-17 grinding wheels.

·5 test glass sheets.

·A set of weights (including 2 500g, 2 750g, and 2 1000g).

·1 touch screen pen.

·1 power cord.

MORE HZinfo

- Mastering Natural Stone Coating: Spray Gun Calibration and Operation Guide

- Nature stone coating,with its authentic stone-like texture, is the premier choice for exterior decoration.

-

2026-01-01

- SI Group Announces Closing of Comprehensive Recapitalization, Positioning the Company for Accelerated Growth

- Significant De-leveraging Transaction Resulting in Overall Debt Reduction of Approximately $1.7 Billion

-

2025-12-31

- BASF to Divest Its Optical Brightening Agent Business to Catexel

- BASF and Catexel have signed an agreement on the sale of BASF’s optical brightening agent business.

-

2025-12-31

English

English 简体中文

简体中文 Русский

Русский إنجليزي

إنجليزي