Paint Defects——EDGE BREAKDOWN

2024-12-25 10:01

Paint Defects--EDGE BREAKDOWN

1.Deion:

Coating failure, usually in the form of corrosion or tearing to edges of a structure. Can also happen to any areas of sharp edges such as welds etc.

2.Probable Causes:

Usually inadequate paint film thickness and/or lack of stripe coats(s). Steel surface may not have any pre-treatment such as a radius of the recommended 2mm.

3.Prevention:

Radius all edges where possible. Dress welds and protrusions. Apply brush/stripe coats at the appropriate time to suit coating system. This may be prior to full coat or after full coat.

4.Repair:

Depends upon extent of coating breakdown. Conduct localised repair where necessary, feather edge existing coating and spot repair. Check compatibility between coats. Dress steelwork as necessary.

5.Interpretation of professional terms:

During the curing process of the coating, factors such as solvent evaporation and further cross-linking reactions can cause the coating volume to shrink and form internal stress. If the internal stress accumulates to a level greater than the cohesive force, the coating will tear. This is particularly evident at the corners, where internal stress and tension from the coatings on both sides are borne. At the same time, the corners usually have a thinner coating thickness, and sharp corners can also form shear forces on the coating like a knife. Therefore, chamfers are very prone to failure, which is commonly known as the "corner effect"

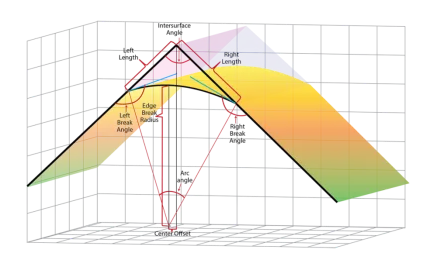

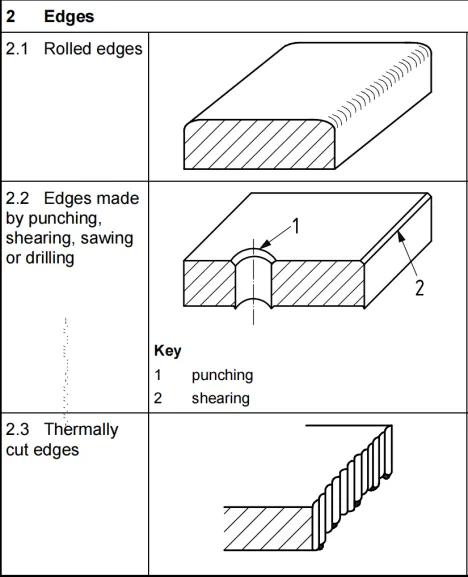

Chamfering refers to the rounding of sharp edges and corners through methods such as grinding and cutting, in order to reduce stress concentration. If the specifications require compliance with the P3 level requirements of ISO 8501-3, chamfering must be performed. The schematic diagram of chamfering methods for different parts is shown in the figure.

More Hzinfo

- Chinese Manufacturer Jiangsu Dynamic Chemical 50,000-Ton Project, Reshaping The Domestic Industrial Landscape

- The unit has commenced smooth, full-process operations yielding high-quality products, contributing to the industry's advancement, and hosted a grand commissioning ceremony.

-

2025-12-26

- Haisheng Coatings Invests 5.5B Yuan in Domestic Supply Base, Targeting Coatings Substitution for High-Speed Rail and Ships

- his marks a crucial step for Haisheng Coatings in expanding its production capacity and extending the industrial chain within the eco-friendly high-performance coatings sector

-

2025-12-26

- Several Chinese Antioxidant Suppliers Raise Prices

- In 2025, the performance of China's leading chemical enterprises has been generally under pressure.

-

2025-12-26

English

English 简体中文

简体中文 Русский

Русский إنجليزي

إنجليزي