Recommended products:Advanced thermal stabilizer for TPU synthesis and film applications – Revonox® U-5068L

2024-09-06 08:44

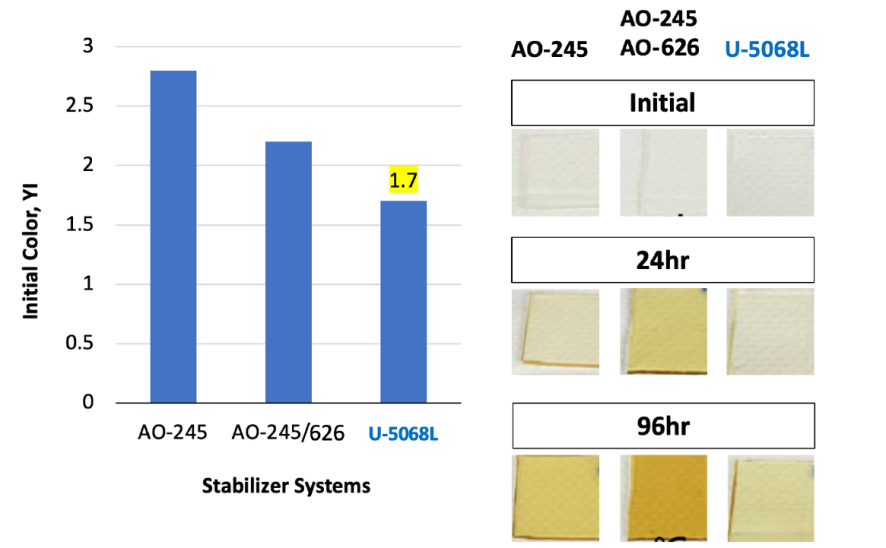

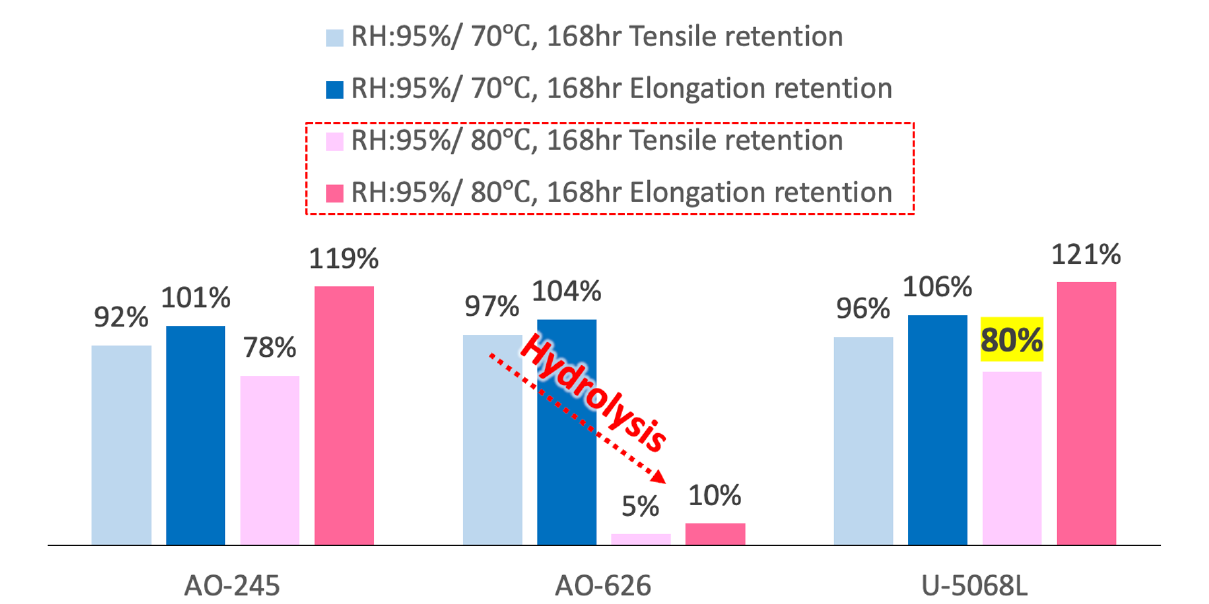

Revonox® U-5068L (U-5068L) is a functional compound thermal stabilizer system specially developed for polyurethane elastomer (TPU). U-5068L is designed with the high-efficiency patented carbon central first aid Revonox® 501 as the core. The ingredients include antioxidants and heat stabilizers to create an excellent synergistic effect. U-5068L is a multifunctional heat stabilizer that provides the required excellent initial color during the polyurethane elastomer synthesis process and can effectively improve the yellowing caused by heat aging during drying (Figure 1). In terms of physical property control, U-5068L will not cause boxing problems. In the operation test of 95% humidity/80℃/168 hours, it still maintained a tensile strength maintenance rate of more than 80% (Figure 3).

In addition, U-5068L will not cause discoloration of smoke. In TPU film applications, U-5068L can effectively inhibit the formation of crystal points, which is a performance that conventional antioxidants cannot provide. U-5068L is suitable for polyether, polyester, or other additives added during the synthesis stage. The recommended addition amount is 0.3-0.5%. For applications requiring oven maturation or long-term thermal baking, the recommended addition amount is 0.5-1.0%.

Revonox® U-5068L Performance Advantages

1. Extremely low initial color

2. Excellent color and physical property control

3. Inhibit the formation of crystal points

4. Does not affect hydrolysis resistance

5. Does not cause discoloration of smoke

◆Performance data

A. Excellent initial color and heat yellowing resistance (Figure 1)

Condition:

Polyester TPU

Antioxidant addition: 0.4%, AO-245/626 ratio = 1/1

AO-245 = CAS# 36443-68-2, AO-626 = CAS# 26741-53-7

Heat aging: 120℃, 96 hours

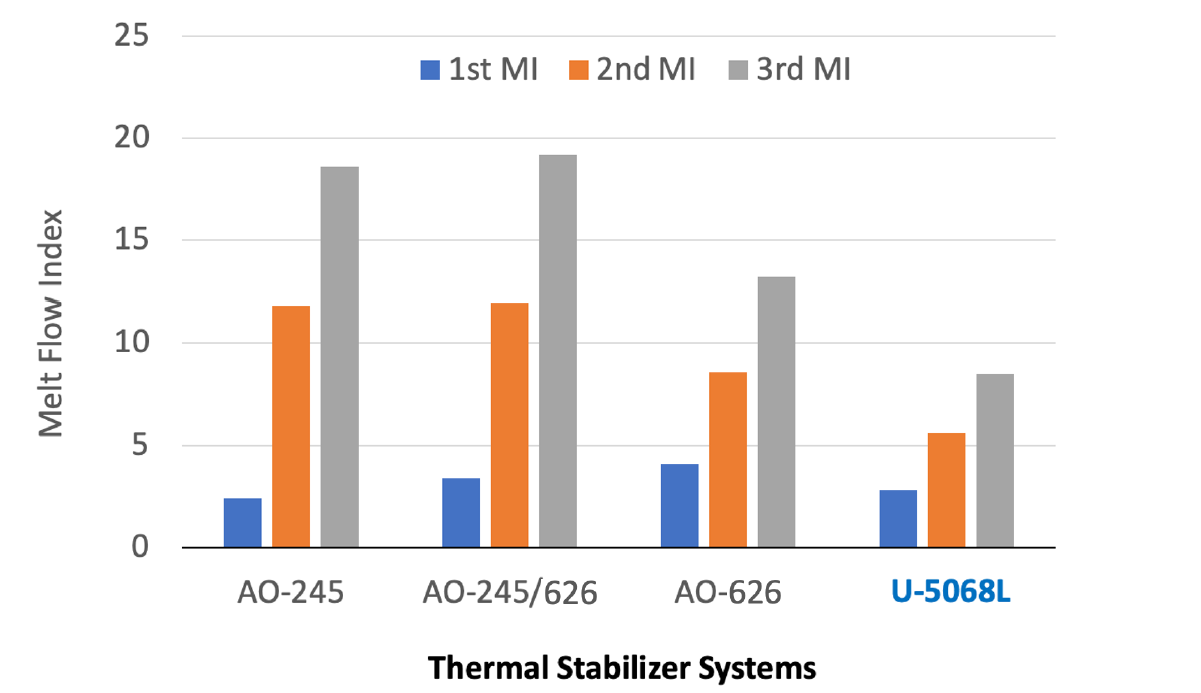

B. Excellent MFI control during multiple extrusions (Figure 2)

Condition :

Polyester TPU

Antioxidant addition: 0.4%, AO-245/626 ratio = 1/1

1.5mm hot press plate (200℃20kgf/cm² 5 minutes), ASTM D412

C. Good hydrolysis stability (Figure 3)

Condition:

Polyester TPU

Antioxidant added: 0.4%

MORE HZinfo

- Ambassador Paint (Anhui) Co., Ltd. Achieves Major Progress in 60,000-Ton Annual Production Project

- Recently, the "60,000-ton annual production project of technological industrial coatings and water-based environmental coatings" by Ambassador Paint (Anhui) has made significant progress.?

-

2025-09-12

- Architectural Coating: Ceramic Sand Coating, Showcasing The Dignified And Elegant Beauty Of Buildings

- As a facade decoration material that highlights the dignified and elegant beauty of buildings, Ceramic Sand Coating boasts numerous highlights.

-

2025-09-12

- Green, Innovation, Cooperation | The Journey of Cadello at the International Coatings Expo Concludes Successfully

- This exhibition not only showcased Cadello's technical and product excellence, but also provided innovative insights for the industry's green transformation.

-

2025-09-12

English

English 简体中文

简体中文 Русский

Русский إنجليزي

إنجليزي